How Does Business Process Reengineering Help Transform Business?

March 31, 2017

Why and How to Jumpstart Your Sales Coaching Efforts

April 19, 2017How To Use The DMAIC Model For Problem Solving?

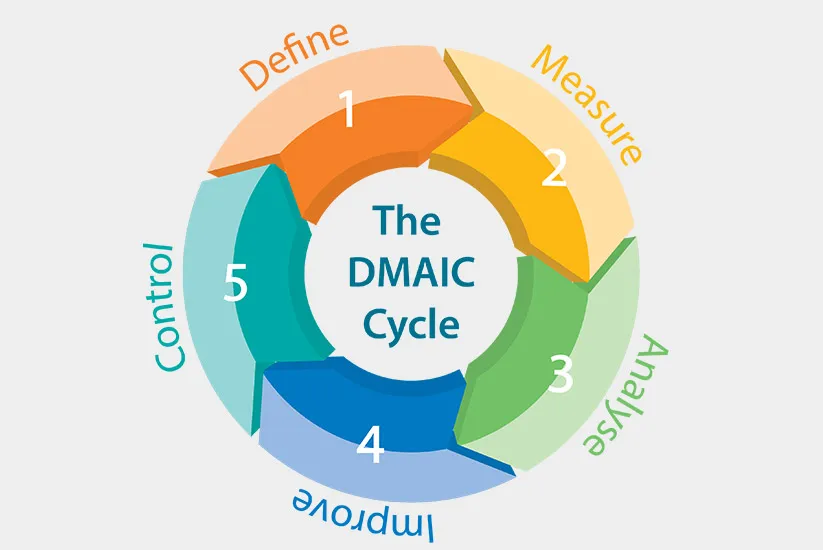

It is very easy to point fingers at and blame someone else for a problem that has occurred. This has become one of the easiest ways of getting away with understanding why the problem has actually occurred, in today’s world. However, this is not the right way of solving a problem, especially not in the corporate world. If you are looking for the right way to analyze, identify, and solve a problem that occurs in your workplace, you must opt for a more positive concept like DMAIC – Define, Measure, Analyze, Improve, and Control.

The DMAIC concept was first created at Motorola in the early eighties, which helped the company earn the Malcom Baldrige National Quality Award in 1988. Slowly and steadily, different companies started using this method, which rapidly gained adoption in teaching thousands of employees how to rightly solve problems by improving processes that were causing those problems. Today, hundreds of companies are using this concept to ensure that they meet the quality expectations of customers effectively and efficiently, thus making it the best way to solve a problem.

Define

This is the first phase of the DMAIC concept, where the problem is defines. It is defines as a question or a situation that calls for a solution. It is very important to clearly define a problem by calculating the frequency of problem occurrence, and the rate of impact when it occurs. Although there are many ways to solve a single problem, but the best approach it to follow the method of DMAIC, and start by defining the problem first.

Measure

This phase establishes the current baseline as the basis for improvement. In this stage, data is collected to establish process performance baselines. This will be compared to the performance metrics at the conclusion of the project to determine whether significant amount of improvement has been made or not.

Analyze

This phase helps to identify, validate, and select the root cause of the problem that needs to be eliminated. Multiple potential root causes are identified via the root cause analysis, out of which the most valid root causes are identified. In this phase, the focus shifts from the effects of the problem to the causes, which are known as factors. This phase is important because it becomes much easier to fix a problem when the root causes are known.

Improve

When you reach this stage, you are ready to generate solutions to the problem. This is where critical thinking techniques need to be applied. The thinking capacity needs to be shifted from the basic thinking techniques to variations of brainstorming like Reverse Thinking, Random World, and Morphological Box. All of these techniques are designed to view a problem through a completely fresh perspective.

Control

This is the last phase of the DMAIC concept that deals majorly with change management. Not all of us are very comfortable with change, which is why any change brought about also brings up quite a lot of resistance. This is why this phase is important as it deals with necessary steps required to maintain the profits made by solving a problem. If this stage is missed out, it is very likely that problems can return back in some time to what they were before.

Using this concept of DMAIC in your workplace, you will definitely help all those working in your organization to determine the right thing to do and ort out problems without blaming or pointing out a finger at someone. You can learn in detail about how to apply DMAIC and other such positive and rewarding concept in your organization by getting in touch with TQMI to achieve its professional and reputed Lean Six Sigma Certification in India.