Competence

As TPM gained popularity throughout the world, TQM International started offering training and consultancy in Middle East & India. The counselors with vast industrial experience and practicing TPM with Japanese in multinational organization got an opportunity to work for TQM International in many well-known multinational organizations in India.

Integration of learning from fabrication & process industries has enabled to offer distinctly unique and highly effective service of its own in this field that has yielded substantial benefits to the client organization. Team highly competent and committed counselors are available to enable client satisfaction of high magnitude.

TQM International follows JIPM approach and the results achieved in industry are laudable.TQM International supports clients for improving Overall Plant Effectiveness with the use of techniques like Autonomous Maintenance, Focused Improvement, Planned Maintenance, Quality Maintenance and Maintenance Prevention along with people capability development.

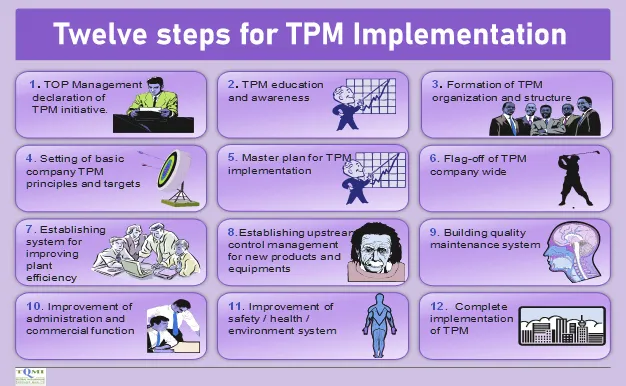

TWELVE STEPS APPROACH IS FOLLOWED FOR IMPLEMENTATION OF TPM:

Trainings Undertaken During The Projects

|

S. No |

Training Module |

Duration |

Participants |

|

1 |

Executive TPM Management Overview |

½ -Day |

Top Managers & Executives. |

|

2 |

TPM Pillars Overview |

½ -Day |

Technical Managers & Executives |

|

3 |

Production System Development (AM and Planned Maintenance Pillars)

|

1-Day |

Technical Managers & Executives |

|

4 |

Why-Why Analysis Workshop – Managers

|

½-Day |

All Top Managers & Executives |

|

5

|

Quality maintenance |

3 - Days |

Technical Managers & Executives. |

|

6 |

KK Pillar & OEE Analysis by graphical method |

½-Day |

All Top Managers & Executives |

|

7 |

P-M Analysis & Design of Experiments |

3 - Days |

Technical Managers & Executives. |

|

8 |

Poka Yoke Design Methodology |

1-Day |

Technical managers & Executives |

|

9 |

Planned Maintenance Pillar |

1-day |

Maintenance Executives. |

|

10 |

Safety, Health & environment pillar |

1-day |

Production & Safety Executives |

|

11 |

Office and warehouse TPM |

1-day |

Marketing, Purchase & Store Executives |

Project Deliverables

- Increase in Overall Equipment Efficiency (OEE).

- Reduction in Defect Ratio.

- Reduction in Accidents.

- Improvement in plant's 5-S.

- Increased Morale of employees.

- Typical ROI is of the order of 5-10 times of the investment made.

Intangible Improvements

- Visible improvement in the Model Areas & Machines within 4 to 5 months.

- Higher degree of employee involvement leading to lower attrition.

- Building people capability leading to improved Quality & Productivity.

- Overall visible improvement in plants after complete horizontal deployment.

- Better Service to the customer.

- Improved price realization/market share.