What is SIX SIGMA?

Six Sigma is the most powerful management initiative of our times, which is benefiting organizations operating in diverse sectors across the globe in terms of increase market share, customer satisfaction, cost reduction and dramatic boost to bottom-line. This methodology is proven in all sectors of industry with fair degree of success.

Six Sigma philosophy is being practiced by many Fortune 500 companies and has already become a way of Life at GE, Motorola, Honeywell, Sony, Nokia, Polaroid etc. These conglomerates have netted multi-million dollar savings by adopting Six Sigma in all their business processes and transactions.

The most distinctive advantage that Six Sigma scores over other quality management initiatives is its link to business results. Realizable gains from Six-Sigma converted in terms of financial benefits, is the key behind Six Sigma success stories. Improvement projects selected are tied to organizations strategy and benefits are linked to the financial reporting system.

Six Sigma is a company-wide philosophy with the use of appropriate techniques to enhance the Business Performance of an organization in terms of cost, quality, productivity, customer satisfaction, employee capability and profitability by reducing the error rate of all outputs of all.

Processes towards 3.4 parts per million.

- The term “Sigma” is a measurement of how far a given process deviates from perfection – a measure of number of “defects”. “Six Sigma” implies near zero defects.

- “A quality improvement methodology that applies statistics to measure and reduce variation in processes.”

- A management system that is “comprehensive and flexible for achieving, sustaining, and maximizing business success.”

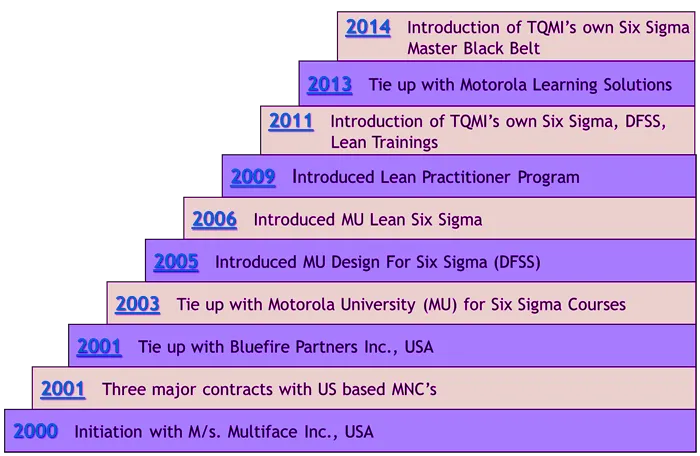

TQM International History of Six Sigma

Key Metrics for Improvement:

Tangible

- Successful implementation of projects:

- 80% project achievement

- Success of Engagement (ROI) > 10:1

- Productivity improvement by 30-100%

- Defect reduction by 5-10 times

- Cycle time reduction by 3-5 times

- Operational cost reduction by 10-20%

Intangible

- Customer satisfaction & business growth

- Enhanced employee capability and morale

- Creation of improvement culture

Our Six Sigma Approach Offers:

- Unique experience of integrating Six Sigma with other Quality / Improvement initiatives like QMS (ISO / TS 16949), Quality Awards, TQM etc.

- Integrating Six Sigma with Knowledge Management System of the Organization, thus ensuring that the concept spreads horizontally and the initial gains accrued by implementing Six Sigma are not fritted away with time.

- Motorola Solution Learning, USA and TQM International have joined hands to develop and deliver Six Sigma offerings in India, the Gulf and USA.

- Effective handholding / facilitation for completion of Six Sigma Projects (success rate > 70% with ROI of 8-10 times)

- Adaptability of the approach to suit the type and size of the business.

- Quick and fast response to client’s need – we ensure that a client’s call for support is responded within 24 hours.

- Competitive prices with assured tangible gains.

- A strong team of 10 Six Sigma Master Black Belt and Black Belt experts widely spread across India.

- Experience of working with Motorola University for more than 8 years.

- Sole Representative of Motorola University in India between 2003 – 2010

- All counselors / trainers have more than 15 years experience and are certified by Motorola University as trainers and coach for Six Sigma.

- All Six Sigma / Lean Six Sigma and Lean Trainings are being offered in Collaboration with Motorola Solutions Learning.

- TQM International was the sole provider of the above trainings in India in collaboration with Motorola Solution Learnings till December, 2014.