This workshop is designed to help manufacturing companies understand the Industry 4.0 concept, look at their organization from this lens, identify opportunities to unlock the value in the information already with the organization, and create a systematic and non-invasive roadmap to unlock this value.

A Journey of Digital Transformation

Manufacturing organizations have always had a single-minded focus on ensuring that their customers are happy, their operations are efficient and sustainable, and the value to their shareholders remains consistently high. They have used every trick in the book to achieve these goals and made large investments in their IT and OT systems. However, with time, the value delivered by these systems reaches a point of diminishing returns as the pressure to improve performance on customer satisfaction, operational efficiency, and shareholder value continues to be relentless.

The above scenario was the motivation behind the introduction of the industry 4.0 architecture, where a new value driver was added to the mix of existing ones. The next big jump in industrial productivity, profitability, and sustainability will come from an asset that has been hiding in plain sight - Information. Unlocking the value of this asset will bring about a paradigm shift in the way a company approaches its customers, designs, produces, and transports its goods, and operates its production assets.

This workshop is designed to help manufacturing companies understand Industry 4.0 concepts, look at their organization from the this lens, identify opportunities to unlock the value in the information already present with the organization and create a systematic and non-invasive roadmap to unlock this value.

Take an Informed Approach to Boost Your Digital Initiatives

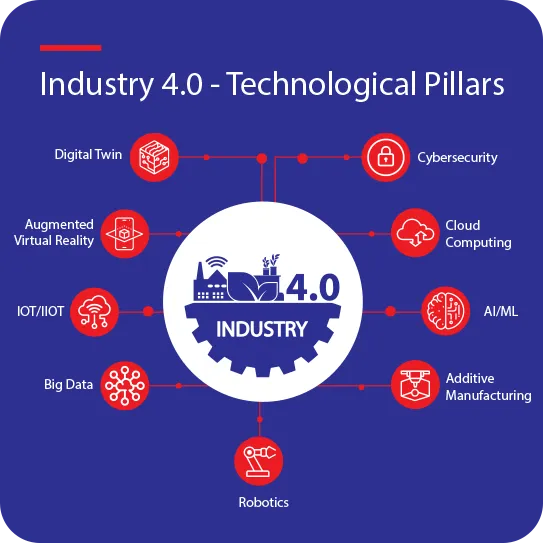

Industry 4.0 is a large topic and covers areas as diverse as process automation, supply chain, production, maintenance, customer relationships, and product design. To make things more complicated, the content available on the internet about Industry 4.0 is fraught with jargon like Machine Learning (ML), Artificial Intelligence (AI), Big Data, Data Science, Robotics, RPA, 3D Printing, Digital Twin, AR/VR, etc. Further, most content on the internet is about a specific case, leaving the big question open – How does this apply to me?

The goal of this workshop is to help accelerate your digitization journey, by distilling all the information about Industry 4.0 components, mapping it to your organization, identifying the elements that would provide the biggest bang for the buck, and organizing it in a systematic roadmap, that can help you scale the maturity ladder step by step.

Your Digital Growth Navigator

The DNA of TQMI is Process Improvement. Our mission is to help our customers improve operational performance, by applying industry best practices. The industry 4.0 architecture is just one of the many tools we bring to bear towards our primary focus of helping customers achieve new levels of performance.

TQMI is a consulting company, not a training organization. This means that we walk the talk, supporting you from understanding to implementation. TQMI becomes your trusted partner in this journey towards achieving operational excellence.

About Delivery

Shripad Lale is an Industry veteran with 33+ years of experience working for Manufacturing digitalization in the building and roll-out of Manufacturing IT solutions. He is a Certified SIRI Assessor (Industry 4.0 Assessment Framework in collaboration with WEF) and has held key roles in organizations like Siemens, TCS, and Schneider Electric.

Based on his experience, he has created his own recipe for the successful adoption of Industry 4.0. In this workshop, he will share key insights which can fast-track your company’s Industry 4.0 program.