Industry 4.0

Industry 4.0

(digital transformation) adoption program ( / projects) success rate is very low; one of the main reasons for failure is not associated to competent business partner.In case if you are looking for Industry 4.0 adoption ( in process / yet to start); your journey for partner identification ends here (hopefully).

Our experience of solving various business problems in 30 years; we realize a competent partner needs to TechnoFunctional and have invested in Subsidiary (CAIZIN) and partner ecosystem.

Does the below problem statements resonate?

If Industry 4.0 adoption measured on a scale from 1 to 100, what is our assessment score? Not sure how to measure this.

What is the Industry 4.0 roadmap for our business objectives?

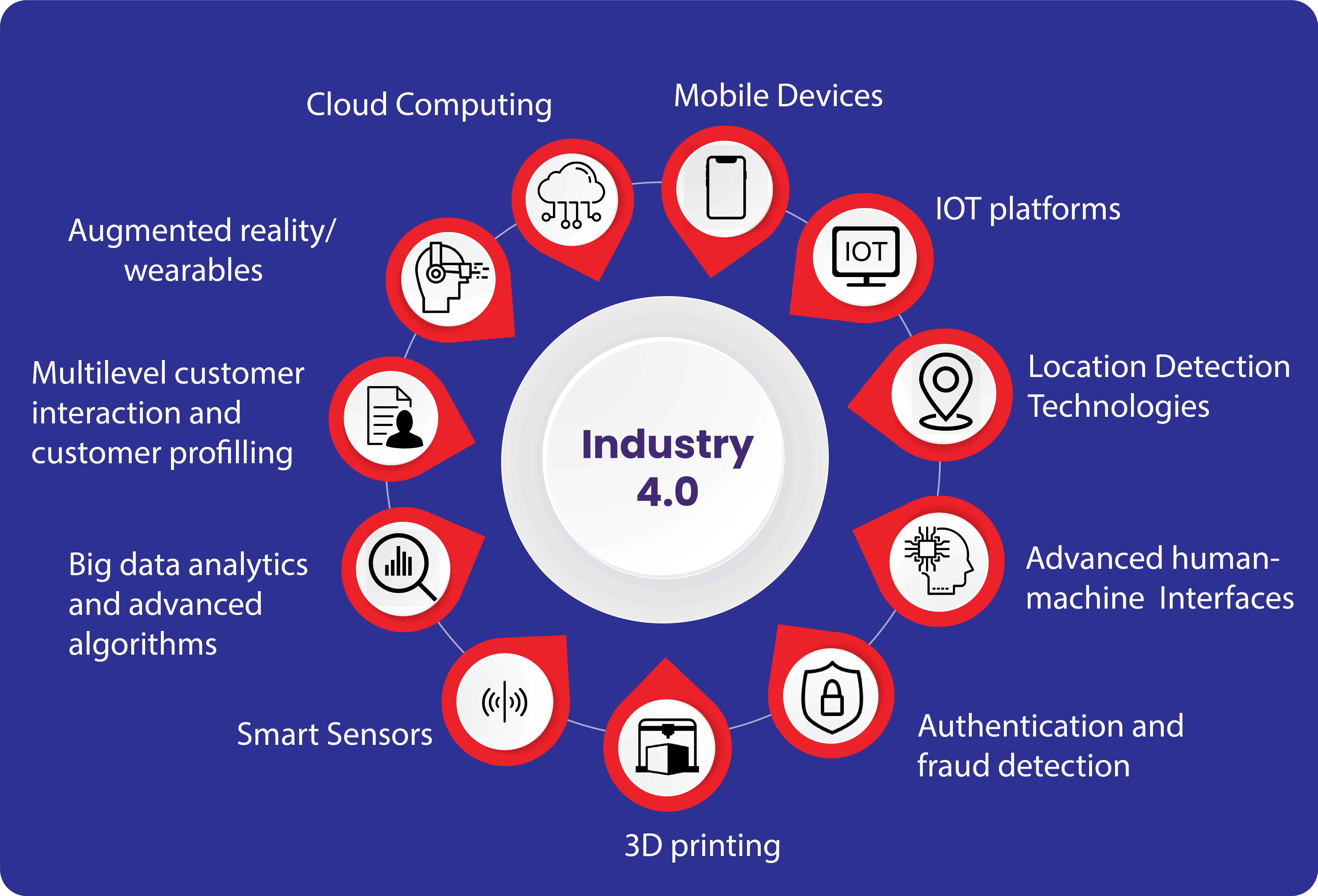

While we hear about AI, ML, Analytics, RPA etc., which technologies should we adopt first?

What should we do for our specific needs?

How do we maximize the impact of our investments?

How do we integrate legacy systems as part of OT-IT integration?

Industry 4.0 Service Portfolio

Discovery

- Quantitative Analysis across organisation representation

- SIRI Assessment Report along with transformational

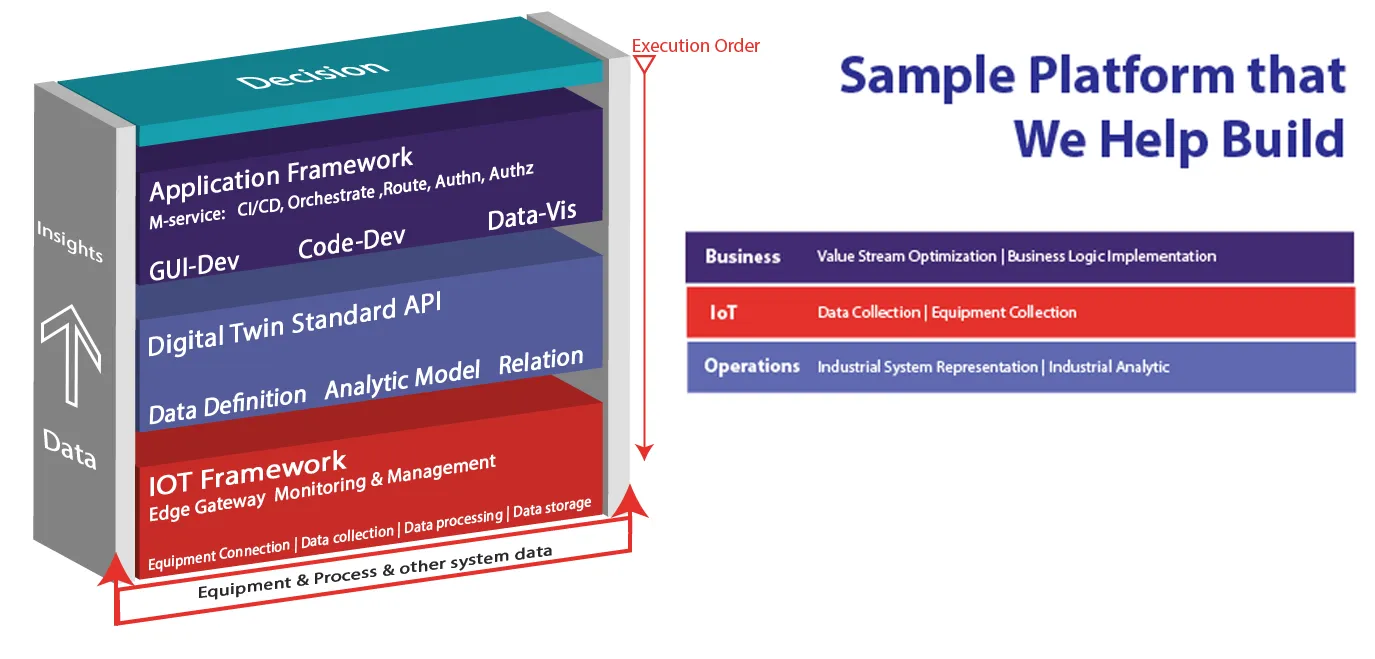

Implementation

- Data Analytics

- Cloud Migration

- Data Security

- Digital Twin

- IoT

Managed Services

- Data Analytics

- Cloud Operation

- Data Security Operations

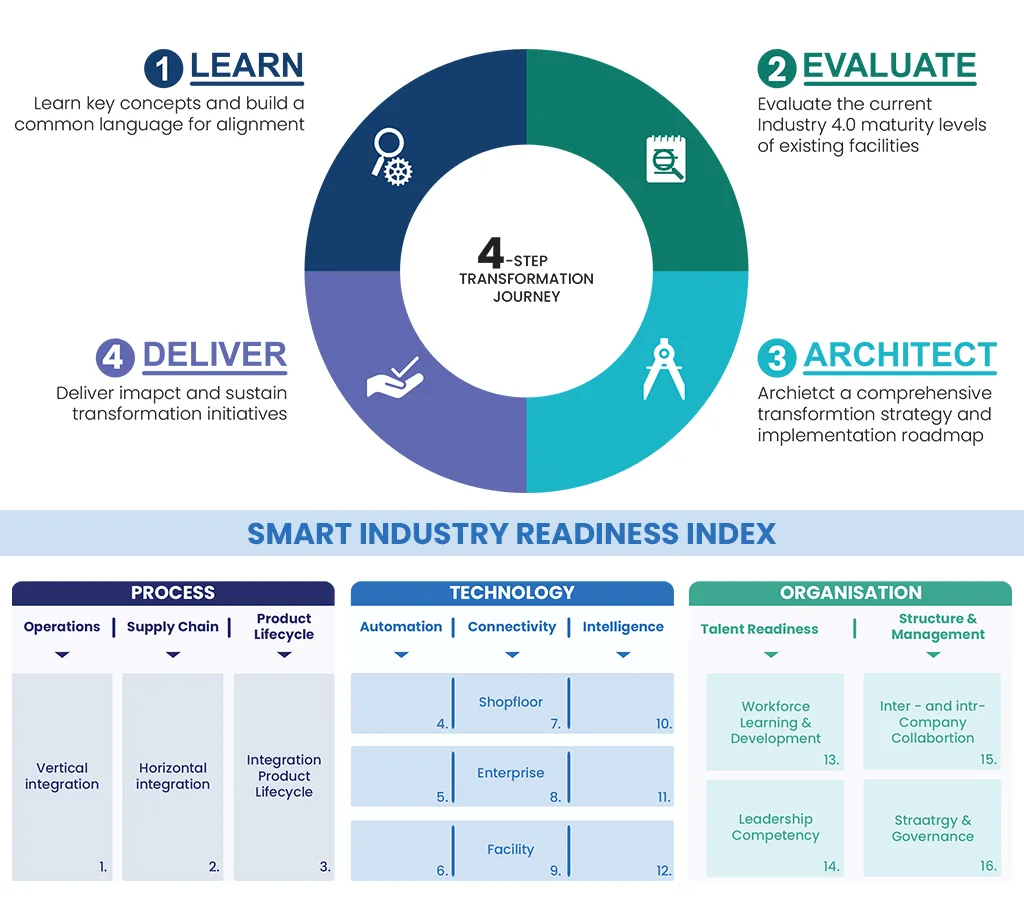

Why SIRI?

The Smart Industry Readiness Index (SIRI) was created by the Singapore Economic Development Board (EDB) in partnership with a network of leading technology companies, consultancy firms, and industry and academic experts. SIRI comprises a suite of frameworks and manufacturers industry 1 - tools to help regardless of size and start, scale, and sustain their manufacturing journeys. SIRI transformation covers the three core elements of Industry 4.0: Process, Technology, and Organisation.

Courtesy:SIRI