How To Have Medical Practitioners Engaged With Lean Six Sigma?

September 19, 2017

What Makes Quality Management System Important For Your Business?

October 3, 2017How To Achieve Success In DMAIC Projects?

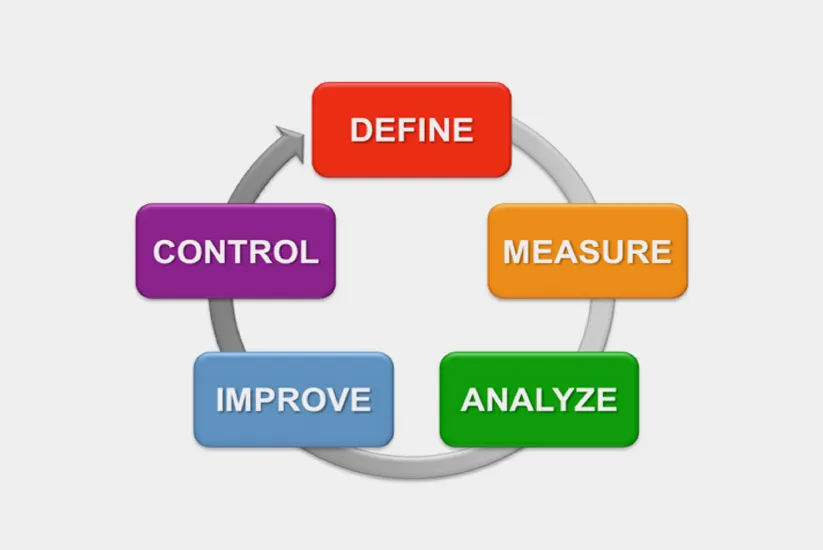

What is DMAIC? It stands for Define, Measure, Analyze, Improve, Control, and is one of the most important approaches of Lean Six Sigma. Lean Six Sigma has a selection of tried and tested tools and methods, which can help in identifying and improving process problems, if applied correctly. More significantly, using the right combination of tools is of utmost importance. One such tool is DMAIC, about which we will learn in detail in this blog.

You must attempt to achieve a Lean Six Sigma, or at least, a Six Sigma certification in India from professionals like TQMI, who can help you acquire the skills and knowledge required for exceptional leadership and management of business improvement projects. Achieving such certification will help you to immediately apply concepts and tools taught in the training sessions to real-time improvement projects, thus achieving quicker results.

Now, let us see how DMAIC is implemented and how it benefits organizations.

Variables and process outcomes with DMAIC

It is important that when applying Lean Six Sigma and its tools, you know the result of a particular phase, which makes it easy to determine the tools that are most suitable to be used at the moment in time. You must also understand that process results are the outcomes of variables within activities. For example, in the case of making a delivery of products, the variables like order size, order complexity, and month of delivery can affect the process result of on-time delivery. Bigger order sizes with complex orders placed during full season can result in late deliveries.

DMAIC can help to determine the variables that have the greatest impact on the results, which can then be improved. DMAIC can describe the goal and problem experienced, measure the potential variables and process performance, analyze the most influential variables, improve the process outcomes, and control the most significant variables and results. In this way, DMAIC serves its purpose of Defining, Measuring, Analyzing, Improving, and Controlling.

Tollgate reviews in DMAIC projects

DMAIC ensures that every phase is carefully and successfully completed, and that the right tools are applied to the right phase. After every phase, a tollgate review is carried out by Black Belts, Green Belts, and Master Black Belts to discuss the results yielded from the phase. Questions regarding the tools used, reason for chosen tools, and contribution of the tools to achieve the project objectives, are considered. And, if the answers are satisfactory, the Master Black Belt permits the execution of the next phase. Conversely, if the results are inadequate and the Master Black Belt finds insufficient potential for process improvement even after the implementation of Lean Six Sigma tools, he has the authority to terminate the project ahead of time. However, all such authority only comes with complete knowledge and experience about Lean Six Sigma and its tools. So, if you are looking for availing such authority within your organization, you can opt for a professional course that can provide you with a valuable and profitable Lean Six Sigma certification in India.