What Career Opportunities Await Six Sigma Green Belts?

May 9, 2017

How Can Lean Six Sigma Affect The Healthcare Industry?

May 24, 2017How Do Six Sigma And Lean Six Sigma Differ?

Is Lean a better system to implement or is Six Sigma for streamlining business processes? This has always been the question by business owners. Both Lean and Six Sigma have their own supporters and critics, while there are others who argue that the best approach to create the most effective business structure is to incorporate both Lean and Six Sigma principles to make it the Lean Six Sigma. Fundamentally, both Lean Six Sigma and Six Sigma have the same goal, and that is to eliminate waste and create the most efficient system. However, they both take different approaches towards achieving that goal. In short, the main difference between Lean and Six Sigma is in identifying the root cause of waste.

Six Sigma

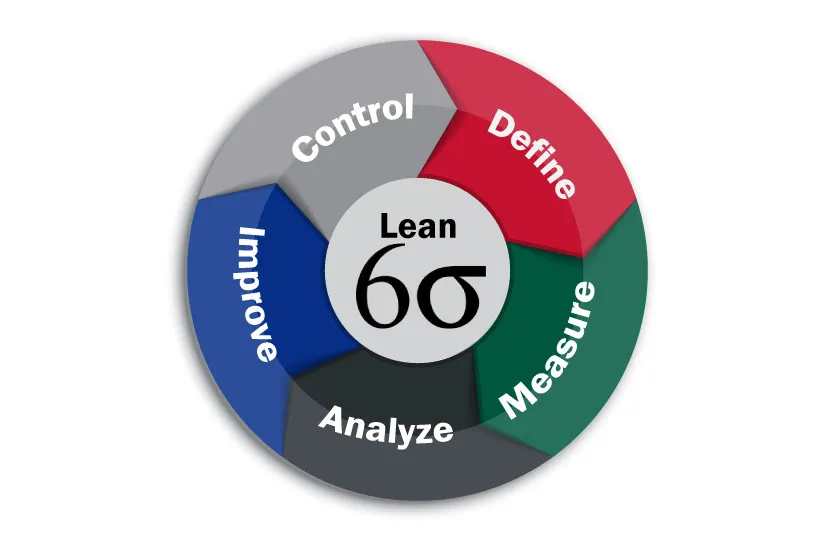

The main aim of Six Sigma is to reduce variation and defect rates in production processes, for which it uses either the DMAIC or the DMADV model. DMAIC is the Define-Measure-Analyze-Improve-Control approach that identifies the problem, takes into account the current process, consider a solution, implement the solution, and maintain it in the future. However, this method only makes adjustments to the current processes, and does not design an entirely new function. On the other hand, DMADV is the Define-Measure-Analyze-Design-Verify approach that uses the same initial three processes, but during the Design phase, allows for the creation of an entirely new tool to solve the problem. Then the Verify phase ensures that the new solution actually continues to solve the problem. Therefore, Six Sigma emphasizes on identifying and eliminating defects to deliver high quality services. The team involved with Six Sigma assists in planning, implementing, and improving the overall profit margin of the business by eliminating all kinds of defects in the production process.

Lean Six Sigma

Lean Six Sigma is the process that entirely focuses on eliminating waste and providing maximum value to the customers with the lowest possible investment, thus streamlining business processes. New processes and allocation of resources are driven with Lean Six Sigma. This process primarily helps to eliminate the eight kinds of waste that don't add value like defects in products, process down-time, overproduction, unutilized talent, surplus inventory, inefficient transportation, unnecessary product movement, and extra processing. Lean Six Sigma is based on the 5S methodology that helps keep production workspace in order, while keeping the work force committed to maintain order. The 5S comprises of Sort, Set in order, Shine, Standardize, and Sustain that help in getting rid of all that is unnecessary in the workplace, and placing all that is important in place, while making sure to maintain the systems and procedures in the future.

So, we can say that both Lean Six Sigma and Six Sigma work towards profit maximization, but with different processes. Six Sigma focuses more on the consumers and end products, while Lean Six Sigma focuses on waste and production methods. Six Sigma believers emphasize that waste results from variations with the processes, while Lean Six Sigma believers claim that waste comes from unnecessary steps in the production process that do not add value to the end product. Obviously, both these assessments are true, which is why both these approaches are successfully being used by businesses to improve their overall performances in a variety of fields.

For the finest Six Sigma Certification in India, you can approach TQMI who has tied up with Motorola Learning Solutions, the inventor of the Six Sigma methodology. You can also avail the most professional Lean Six Sigma Certification in India here, may it be Green Belt, Black Belt, or Master Black Belt!