How 5S, Lean, and Six Sigma Complement Each Other

November 17, 2021

Policy Management and TQM: Its Evolution And Benefits

December 9, 2021What is SIRI Assessment and How does it help Industry 4.0 Initiatives?

Industry 4.0 is the new mantra for companies to have a competitive advantage but how can enterprises ensure that they meet these effectively without spending a huge amount of money on Industry 4.0 Implementation? There is a way and that's by using the SIRI assessment.

The SIRI or Smart Industry Readiness Index is a great way to analyze whether your manufacturing company is optimally functioning.

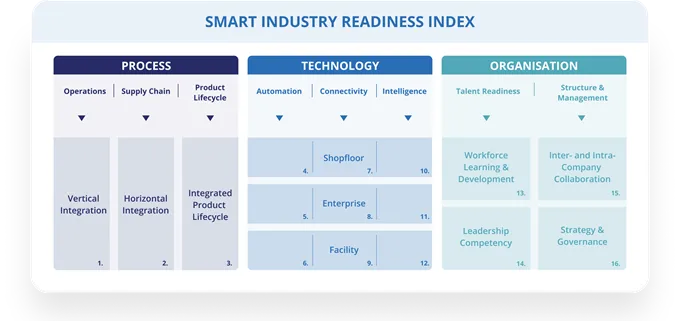

The Smart Industry Readiness Index (SIRI)

Image courtesy - SIRI

Industry 4.0 relies on a high level of digitalization. While there may be a lack of clear vision, strategy, and a roadmap of how to implement this, there's still a need for change. SIRI acts as a way to address these challenges. The test was created in partnership with a global testing, inspection, and certification company called TÜV SÜD. A panel of industry and academic experts have validated it.

SIRI includes frameworks and tools that help manufacturers of all sizes and industries start, scale, and sustain their Industry 4.0 transformation journey

The SIRI framework consists of three layers.

- The top-most layer is made of three essential elements for Industry 4.0, namely process, technology, and organization.

- The second layer comprises eight areas. These represent critical aspects that companies must focus on to become future-ready.

- The final layer has 16 dimensions that companies can use when they're evaluating their facilities' current maturity levels.

Technology

Advancements in technology have been the cornerstone of industrial revolutions throughout history. It's still a critical part of Industry 4.0s evolution with technologies such as cloud computing, machine learning, and the Internet of Things (IoT) leading the way

Today's landscape is hyperconnected. This has been further divided into automation, connectivity, and intelligence.

- Automation: This is the 'muscle' for Industry 4.0. As a key enabler for companies, automation must now be both efficient and flexible. That will allow companies to generate a large product range in smaller batches. These don't need to invest in significant capital over time. They don't need to be redesigned either. That puts manufacturers in a better position competitively. It helps them pursue a large number of global business opportunities. It will also help suit rapidly changing customer needs.

- Connectivity: This is the CNS. With IoT at play, today we've become more interconnected than ever before. While this is great for companies, it does give rise to certain other issues. The main problem with this would be cybersecurity. Hyper-connected operations increase the number of vulnerable points in a system. That would give way to more cyber-attacks. It also increases the severity of cyberattacks as attackers would have access to more info than ever. Risk needs to be mitigated.

- Intelligence: This is the brain powering Industry 4.0. With the cloud, data analytics, machine learning, and other systems, our systems are more intelligent than ever before. Huge amounts of data are generated, processed, and translated into actionable insights. At their best, they can make decisions autonomously and respond to internal and external business needs.

Process

This is divided into operations, the product life cycle, and the supply chain. These are essential for technological investments to be channeled into the appropriate streams. As the processes with these become integrated, they converge into a single unified system where information is shared, processed, and integrated.

That's done across the organization’s product management, production, and enterprise layers.

- Operations: Companies use data analytics to reduce waste by figuring out inefficient processes. They also use wireless communications to connect discrete processes, enabling remote monitoring and decentralization of the control of assets.

- Supply Chain: Digitalizing supply chains allow decisions about inventory, cost, and operations to be made from an end-to-end perspective. Digitized workflows benefit all players along the value chain. These also power greater effectiveness, efficiencies, flexibility, transparency, and more.

- The Product Life Cycle: The information generated at each stage is shared seamlessly, creates better decision-making, and enables processes to be optimized in other stages. It also removes the limitations of working with physical prototypes. These can now be created at any speed, scale, and at a lower cost.

Organization

This is the third building block of Industry 4.0. Its first component is the organization’s people which includes the entire workforce. That's from the top management down to the operational teams. The second component is the institutional systems that govern the functioning of the company. These must both be taken into consideration to fully benefit from industry 4.0.

A competent leadership team and labor force will be demotivated by rigid rules, inconsistent practices, and more.

It's also important to have open channels of communication. Many companies adopt an open-door policy so that their employees can benefit from a flat hierarchy. These divisions can be named Talent Readiness and Structure and Management.

- Talent Readiness: This refers to development programs that are aligned with the company's business objectives and HR plan. These would create a culture of self-learning, personal development, and more. It will result in a skilled workforce and a core leadership that will maximize the value of any company initiative.

- Structure and Management: A robust structure and management process will help an organization become more flexible, collaborative and empower them to design and implement industry 4.0 strategies effectively.

How does SIRI help in your Industry 4.0 initiatives?

The Assessment Matrix

This is the world's first self-diagnostic industry tool that helps companies globally regardless of their size and industry. It helps start, scale, and sustain their digital transformation and the tool breaks down each of the 16 SIRI dimensions into 6 progressive bands of maturity

Companies can use this metric to evaluate their digital maturity and set benchmarks for themselves.

The Prioritization Matrix

The prioritization matrix helps companies manage their high-priority SIRI dimensions. These would deliver the greatest impact on their organization.

This tool was developed with the support of McKinsey and Company, Siemens, and many other global leaders.

Essentially, the SIRI framework provides a system that's been created, tested, and approved by industry experts. These help companies understand where they are lacking and create better processes, with KPIs in place. This is the best way to boost industry initiatives and transform your company holistically, steadily, and efficiently.

At TQMI, we have designed a special workshop to help manufacturing companies understand and rightly adopt Industry 4.0. As a part of this workshop, we look at your organization from the lens of smart manufacturing adoption, identify opportunities to unlock the value in the information already with the organization, and create a systematic and non-invasive roadmap to unlock this value.

This workshop is conducted by a Certified SIRI Assessor and industry veteran with 33+ years of experience working for Manufacturing digitalization in the building and roll-out of Manufacturing IT solutions.