Four wheeler auto manufacturers

QMI is also working for a world class four wheeler auto manufacturers. This company believed that since the business dynamics around the world were changing very fast thus leading to increase in demand of higher and higher operational efficiencies.

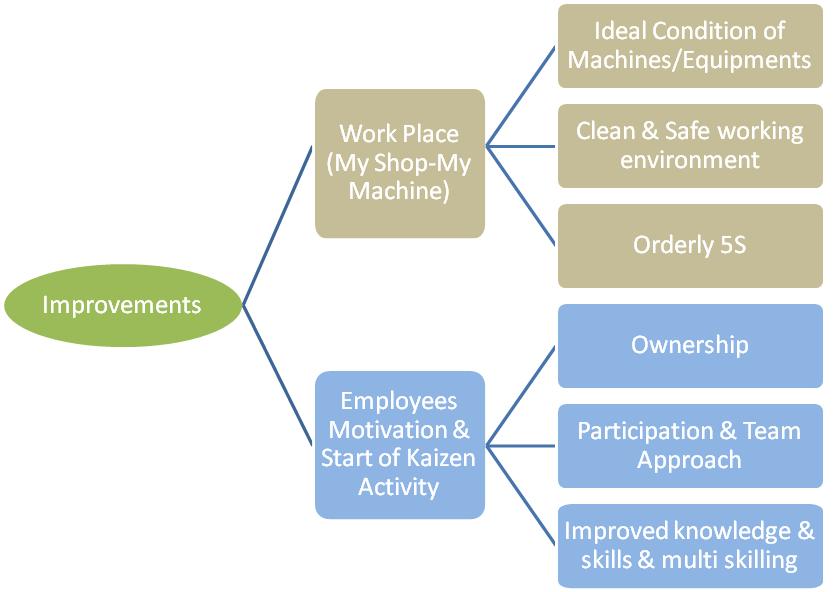

To achieve this the company decided to work towards best possible improvements in operational areas through efficient operations resulting in improving cost efficiencies and contribute to improve profitability situation by adopting TPM and thus reaping rich benefits through this robust management system.

The company decided that they needed to play an important role to contribute to the improvement in product reliability while minimizing waste and cost through capable motivated and joyous people.

Through adoption of TPM the Management selected a few vital objectives through TPM project as follows:

Enhancing the optimal use of plant assets by

- Improving plant (equipment) reliability and maintainability including optimization of maintenance.

- Increasing productivity and equipment availability through Autonomous Maintenance.

Reducing wastage across the plants.

- Cost reduction through elimination of losses & reducing resource inputs.

Reducing the maintenance cost of assets by

- Controlling optimal usage of spares including inventory.

- Reducing resource inputs.

- Attaining sustained quality by reducing in-process defects and customer complaints.

Making work place vibrant, joyful, safe, and accident free by

- Improving work environment & improving operators morale.

Tangible Benefits

|

P |

Parameter |

Metrics |

Present Status after 18 months of Kick off |

|

Overall Line Effectiveness (OLE) |

Percentage |

Improved from 80% to 86% |

|

|

Equipment failure reduction time |

Percentage |

Equipment Down Time reduced by 40% |

|

|

Q |

Defect & Rework loss |

Percentage |

Reduction by 30% |

|

D |

Delivery |

Percentage |

Achieved around 100% |

|

S |

Minor Accidents |

Nos |

Reduced to Zero |

|

M |

No of Kaizens |

Nos/Person/Month |

Improved by 50% |

Intangible Benefits